YZS series vibrating screen suitable for mining, building materials, road and railway, energy, chemical industry and other industries, which is the ideal equipment in the crushing and screening line.

Applications: Various aggregates and mineral product' s screening

+86-13585707741*24-hourWhatsapp/Wechat

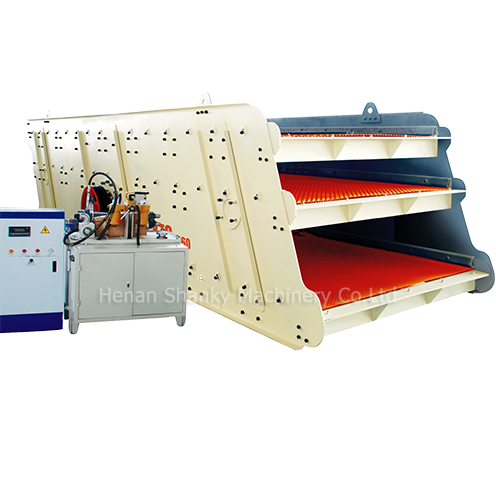

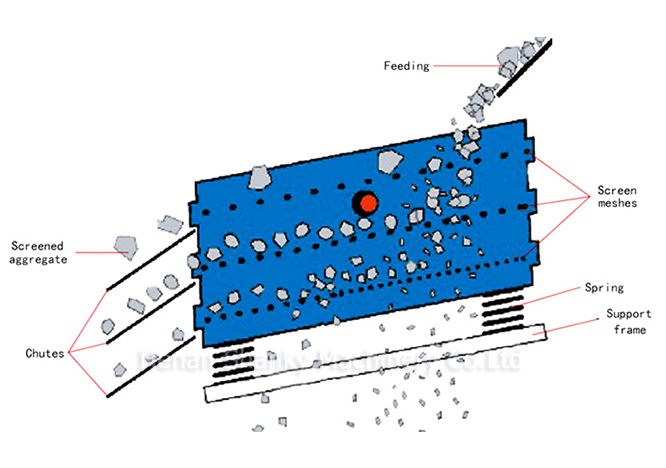

YZS series circular vibrating screen adopts the internationally mature design concept at present, and is suitable for various screening operations such as large, medium and fine screening. It is an ideal equipment for handling materials after primary crushing and secondary crushing, and can also be used for screening finished materials. YZS circular vibrating screen is mainly composed of screen box, spring support device, Support seat, vibrator, transmission device, motor, transmission device support seat and other components.It is a device that uses springs as supporting elastic elements and eccentric block vibration exciter as vibration source to generate excitation force through the rotation of eccentric blocks, so that the screen box will generate circular reciprocating motion. The material continuously makes a nearly circular bouncing and rolling motion on the inclined screen surface. Through repeated comparison with the screen mesh, the material smaller than the size of the screen mesh passes through the screen, and the material larger than the size of the screen mesh is on the screen surface, thus completing the screening process.

The side plate adopts the whole plate laser cutting technology without welding, and the structural parts are riveted by high-strength bolts.

YK series circular vibrating screen mainly consists of the eccentric block vibrator, screen box, motor, and supportive device. Its vibrating track is a circle and moves on a circular motion. It is a multi-layer and high efficient vibrating screen. Motor drives the V-belt to make the eccentric block rotate in high speed, so that producing large centrifugal force to make exciter produce the amplitude in circular motion, the stone aggregates on the screen surface will be throwing motion continuously under the function of exciter, during the process of materials contacting with the screen surface, final products will be classified.

| Model |

Screen Size(mm) |

Layer |

Max.Feeding Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Vibrating Frequency (r/min) |

Double Swing (mm) |

| 2YZS-1237 | 3700×1200 | 2 | 300 | 25-120 | 11 | 890 | 5-9 |

| 3YZS-1237 | 3700×1200 | 3 | 300 | 25-120 | 11 | 890 | 5-9 |

| 2YZS-1548 | 4800×1500 | 2 | 300 | 30-275 | 15 | 890 | 5-9 |

| 3YZS-1548 | 4800×1500 | 3 | 300 | 30-275 | 15 | 890 | 5-9 |

| 4YZS-1548 | 4800×1500 | 4 | 300 | 30-275 | 18.5 | 890 | 5-9 |

| 2YZS-1848 | 4800×1800 | 2 | 350 | 56-330 | 15 | 890 | 5-9 |

| 3YZS-1848 | 4800×1800 | 3 | 350 | 56-330 | 18.5 | 890 | 5-9 |

| 4YZS-1848 | 4800×1800 | 4 | 350 | 56-330 | 22 | 890 | 5-9 |

| 2YZS-1860 | 6000×1800 | 2 | 350 | 65-586 | 18.5 | 890 | 5-9 |

| 3YZS-1860 | 6000×1800 | 3 | 350 | 65-586 | 22 | 890 | 5-9 |

| 4YZS-1860 | 6000×1800 | 4 | 350 | 85-586 | 30 | 890 | 5-9 |

| 2YZS-2160 | 6000×2100 | 2 | 350 | 81-720 | 22 | 890 | 5-9 |

| 3YZS-2160 | 6000×2100 | 3 | 350 | 100-720 | 30 | 890 | 5-9 |

| 4YZS-2160 | 6000×2100 | 4 | 350 | 100-720 | 37 | 890 | 5-9 |

| 2YZS-2460 | 6000×2400 | 2 | 350 | 150-850 | 30 | 890 | 5-9 |

| 3YZS-2460 | 6000×2400 | 3 | 350 | 150-850 | 37 | 890 | 5-9 |

| 2YZS-2870 | 7000×2800 | 2 | 350 | 120-680 | 22*2 | 750 | 7-11 |

| 3YZS-2870 | 7000×2800 | 3 | 350 | 180-720 | 22*2 | 750 | 7-11 |

| 2YZS-3075 | 7500×3000 | 2 | 400 | 200-1200 | 22*2 | 800 | 7-12 |

| 3YZS-3075 | 7500×3000 | 3 | 400 | 200-1200 | 30*2 | 800 | 7-12 |

| 2YZS-3680 | 8000×3000 | 2 | 400 | 225-2250 | 30*2 | 850 | 7-12 |

| 3YZS-3680 | 8000×3000 | 3 | 400 | 225-2250 | 37*2 | 850 | 7-12 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13585707741*24-hourWhatsapp/Wechat