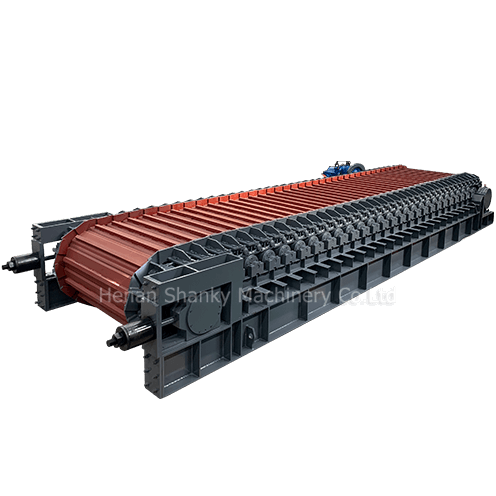

It is widely used to transport large-volume materials to various crushing equipments uniformly and continuously in a short distance.

Applications: It is especially suitable for transporting large,high temperature and sharp materials,and it can reliably work in harsh and humid outdoor environments.

+86-13585707741*24-hourWhatsapp/Wechat

Vibrating feeder is also known as vibrating feeder. GZD vibration feeder produced by our company is a new type of vibration feeder designed for conveying large materials evenly before crushing and screening medium coarse crusher. Vibration feeder adopts the structure characteristics of double eccentric shaft vibrator to ensure that the equipment can bear the impact of large material falling, and the feeding capacity is large. In the production process, the block and granular materials can be evenly, regularly and continuously given to the receiving device from the storage bin, so as to prevent the receiving device due to uneven feeding and the phenomenon of crash, prolong the service life of the equipment. The feeder can be divided into steel plate structure and grate structure. The feeder of steel plate structure is mostly used in sand and stone production line, and all the materials are uniformly sent into the crushing equipment; Grate structure of the feeder can be coarse screening of the material, so that the system is more economical and reasonable in the preparation, has been used as an essential equipment in crushing and screening.

Please consult customer service!

|

Model |

LBJ-1000x5000 |

LBJ-1300x6000 |

LBJ-1500x8000 |

LBJ-2000X10000 |

|

|

Max.Feeding Size(mm) |

≤600 |

≤800 |

≤1100 |

≤1500 |

|

|

Capacity (t/h) |

100-500 |

150-750 |

300-1000 |

550-1580 |

|

|

Max. Tilt Angle |

20° |

20° |

20° |

20° |

|

|

Motor (inverter)(kw) |

11-15 |

15-18.5 |

22-37 |

90-110 |

|

|

Feed Chute. |

Plate Width (mm) |

1000 |

1300 |

1500 |

2000 |

|

Plate Thickness(mm) |

20 |

20 |

20 |

25 |

|

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13585707741*24-hourWhatsapp/Wechat