Hydro power, railways, highways, concrete mixing stations, ore crushing and other industries;

Applications: Granite, limestone, concrete, limestone, coal, calcium carbide, quartz, dolomite, iron sulfide.

+86-13585707741*24-hourWhatsapp/Wechat

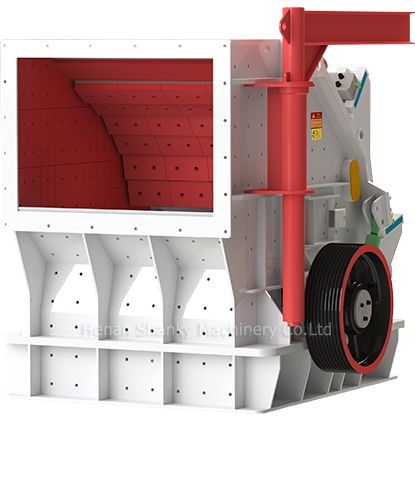

P6S European impact crusher is manufactured according to advanced European technology, combined with working condition of sand and gravel industry. Abrasion resistance material and perfect crushing cavity bring superior capacity to the P6S crusher .High-class forging for main shaft and no-board design, advanced international taper-lock connection makes it reliable to operate and easy to maintain. It is widely used for highway, water conservancy, electricity and construction.

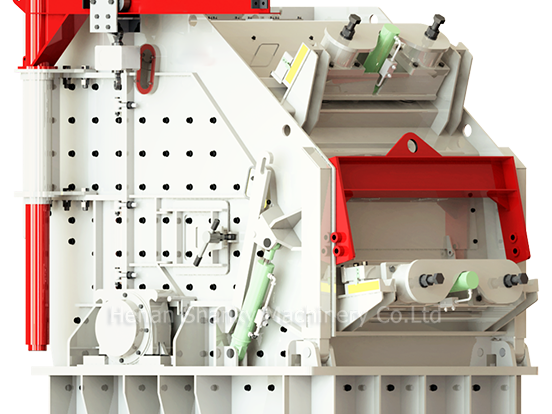

By adopting the three combination design of open box,hydraulic hoisting device and maintenance hoisting, the rapid completion of the hammer and other wearing parts replacement in short time, reducingDowntime and maintenance time, reducem aintenance costs.

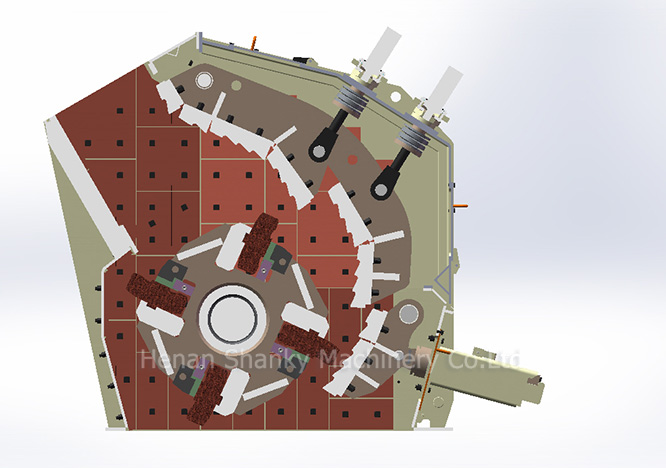

Adopting heavy-duty rotor design, which enable its owns greater rotatory inertia That means, with the same rotate speed,it has stronger crushing force, high efficiency.

External scale, can easily grasp the distance between the plate hammer and the Impact rack.

Hydraulic automatically adjust the gap between the Impact rack and the plat ehammer, effectively reducing labor time and intensity, fast, convenient and safer.

Adopting wedge to fix the plate hammer,re;reliable work, convenient changing,ensure roller to be firm under high-speedrotation.

The design of constant tension device maintains constant counter force,decrease the powder consumption.

Heavy-duty bearing and pedestal adopt overall forging steel, which can perfectly fit the crusher frame and increase the radial force of bearing pedestal Excellentwaterproof and dust proof effect can protect the bearing.

Hammer adopts crescent, which can ensure the material to crush vertically with great impact strength, high crushin gefficiency. It effectively reduces thedamage of the impact surface after thewear of the traditional impact hammer.

liner type is more uniform, interchangeable use, reduce the replacement cost of easily damaged parts.

When Impact crusher works, under the driving force of motor, the rotor rolls at a high speed with the blow bar on it hitting the material into pieces, and then the material will be thrown toward the impact device and then to the blow, so it will be crushed again. This process repeats until materials are crushed to the requested size. The product size and output can be controlled by adjusting the clearance between impact plate and blow bar. This impact crusher is designed with spring safety device,when non-crushing material enter into crushing chamber, the impact rack will recede and then the non-crushing is discharged.

| Model |

Output size ( mm) |

Ma×.Feeding Size(mm) |

Capacity(t/h) |

Power(kw) |

Dimension(mm) |

| P6S1010 | 20-100 | 400 | 100-200 | 90-110 | 2800×1925×2305 |

| P6S1210 | 20-100 | 450 | 140-285 | 110-160 | 2871×1967×2600 |

| P6S1214 | 20-100 | 550 | 200-300 | 160-200 | 2871×2307×2600 |

| P6S1315 | 20-200 | 600 | 250-350 | 200-250 | 3166×2580×2721 |

| P6S1317 | 20-200 | 600 | 250-400 | 200-315 | 3175×2781×2660 |

| P6S1420 | 20-200 | 900 | 300-500 | 315-355 | 3582×3205×3118 |

| P6S1520 | 20-200 | 900 | 400-600 | 400-500 | 3857×3629×3440 |

| P6S1620 | 20-200 | 1200 | 450-700 | 400-500 | 4056×3395×3356 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13585707741*24-hourWhatsapp/Wechat