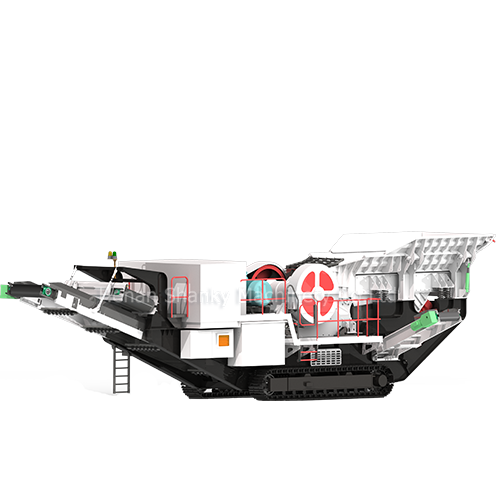

Jaw Crawler Mobile Crushing Station is new type stone crushing equipment. It integrates feeder, stone crusher, screening equipment to effectively solve site infrastructure. Mobile crusher plant is widely used in building, road and bridge construction, urban construction

Applications: Stone crusher is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate etc. Different final output size could meet your different needs.

+86-13585707741*24-hourWhatsapp/Wechat

Jaw Crawler Mobile Crushing station is equipped with a high performance jaw crusher, and vehicle-mounted feeder with high-intensity ,short length, light weight; strong mobility adaptability, reduce material transportation cost, flexible combination , Whether crushing or sand making operations, its design philosophy is to fully adapt to the various mobile crushing circumstances, eliminate broken space, the environment, the customer base configuration crushing plant obstacles, provide customers with real simple, efficient crushing equipment. It mainly used in metallurgy, chemical industry, building materials, utilities that often need to move for material processing operations, especially for highways, railways, hydro-power engineering and other stone work flow, users can process raw materials according to the type, size and product requirements of different materials using a variety of configurations.

Crawler mobile crushing station products have light weight, small volume, especially suitable for narrow site work.

The high-quality jaw crusher specially designed for mobile station is highly independently researched and developed, which perfectly fits the production conditions.

Set material receiving, crushing, transmission and other process equipment as a whole, through the optimization of the process flow to make it has the crushing performance of rock crushing, aggregate production, open-pit mining, through the joint of different models, to form a strong crushing operation line, complete the multiple-demand processing operations.

The whole machine adopts all-wheel drive, can realize in-situ steering, standard configuration, quick change device, with perfect safety protection function, especially suitable for narrow and complex area.

Fuel saving, fuel saving rate up to 25%.

Random attached power group - optimization design.

It can work uphill to meet the crushing requirements of mining, hydro-power station, coal mine and other projects.

Jaw Crawler Mobile Crushing Station is one kind of mobile rock crusher. According to the different requirements of different crushing process, Mobile crushing and screening plants can be the following two processes of "crushing first, screening second" or "screening first, crushing second". The mobile stone crushing plant can be composed of two-stage plants or three-stage plants. The two-stage plants consists primary crushing system and secondary crushing system, while the three-stagesystems includes primary crushing plant, middle crushing plant and tertiary crushing plant, each of which is of high flexibility and can be used individually.

|

Item |

MC-C106 |

MC-C116 |

|

Capacity(t/h) |

140-420 |

170-600 |

|

Host Type |

C106 |

C116 |

|

Feeding Capacity(t/h) |

430 |

600 |

|

Max Feeding Size(mm)(mm) |

650 |

680 |

|

Discharge Opening Adjustment Range(mm) |

70-200 |

80-200 |

|

Main Belt Conveyor(W*L)(mm) |

1000×10000 |

1200×12000 |

|

Main Engine Power(KW) |

110 |

132 |

|

Overall Power(KW) |

200 |

250 |

|

Transport Size(L*W*H)(mm) |

14900×3000×3600 |

15200×3200×3700 |

|

Total Weight(t) |

45 |

58 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13585707741*24-hourWhatsapp/Wechat