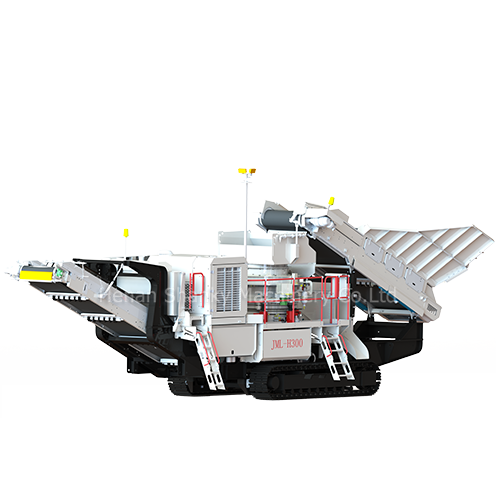

Cone Crawler Mobile Crushing Station is mainly used in hard rock crushing, aggregate production, mining crushing, construction waste recycling. It provides a new field of business opportunities for contractors, quarry operators, recycling and mining applications.

Applications: Cone Crawler Mobile Crushing Station is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate etc. Different final output size could meet your different needs.

+86-13585707741*24-hourWhatsapp/Wechat

Cone Crawler Mobile Crushing station is suitable for crushing and processing of natural stones and minerals with medium high hardness and high abrasion. This equipment integrates mechanical, hydraulic, electrical, automation and other technologies. It has many advantages, such as high crushing efficiency, low production cost, convenient maintenance and adjustment, and excellent particle size of crushed products. It can show the characteristics of large energy production, good particle shape, low energy consumption, etc. in the secondary or tertiary crushing processing application of medium high hardness, medium high abrasive natural stone materials, such as granite, basalt, diabase, etc. This series of equipment is not afraid of narrow terrain and harsh environment, and is the mainstream product in the construction industry and metal mining industry today.

The ship shaped steel frame structure is adopted, and the chassis design is compact, effectively shortening the transportation length.

The high-quality Cone crusher specially designed for mobile station is highly independently researched and developed, which perfectly fits the production conditions.

The main machine of cone crusher has a variety of different cavity types available to meet the production requirements of different product sizes.

Full hydraulic control is accurate and reliable. The equipment is hydraulically operated from cavity cleaning, overload protection to adjustment and locking.

Stable and reliable operation and convenient operation. The hydraulic system structure is comprehensively optimized and upgraded, the regulation and control are more accurate, and the automatic protection response is more sensitive.

The hydraulic outrigger that can be raised independently can effectively avoid the phenomenon of deflection caused by uneven ground support and uneven strength.

The motor drives movable jaw assembly do reciprocating motion according to the desired trajectory under the action of belt and pulley. The angle between toggle plate and movable jaw increases when movable jaw moves up and the movable jaw closes to the fixed jaw. The materials are crushed in this process. The angle between toggle plate and movable jaw decreases when movable jaw moves down and movable jaw moves away from fixed jaw under the action of the tension rod and spring, then products after being crushed are discharged from the discharge opening.

| Item |

MC-H300S |

MC-H400S |

|

Capacity(t/h) |

100-380 |

150-450 |

|

Host Type |

HP300 |

HP400 |

|

Feeding Capacity(t/h) |

500 |

500 |

|

Max Feeding Size(mm)(mm) |

180 |

210 |

|

Discharge Opening Adjustment Range(mm) |

10-45 |

10-45 |

|

Main Belt Conveyor(W*L)(mm) |

1000×10000 |

1200×11000 |

|

Main Engine Power(KW) |

220 |

315 |

|

Overall Power(KW) |

350 |

500 |

|

Transport Size(L*W*H)(mm) |

19000×3900×3800 |

19500×3900×3800 |

|

Total Weight(t) |

58 |

65 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13585707741*24-hourWhatsapp/Wechat