Mining, smelting, building materials, roads, railways, water conservancy andchemical Industries

Applications: Limestone, granite,marble, basalt, iron ore, river pebbles, shale, bluestone, coal, cobblestone, construction waste, etc

+86-13585707741*24-hourWhatsapp/Wechat

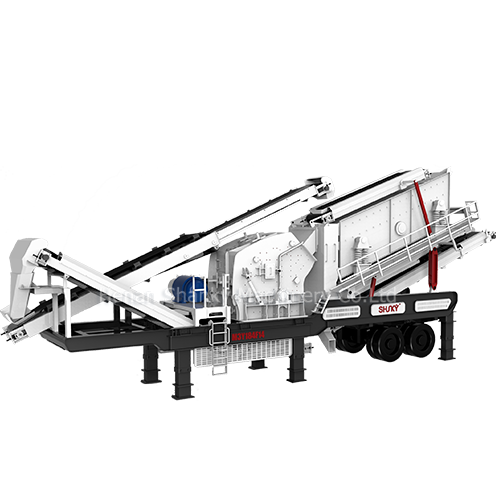

Impact type tire mobile crushing station, equipped with high-performance PF impact crusher, high crushing efficiency, multifunction , excellent quality of crushing products, with light and reasonable structure design, good crushing performance. Reliable and stable quality assurance, a wide range of meet the coarse, medium and fine material crushing and screening requirements. Not only the technology is mature, easy to operate and maintain, but also has good adaptability and reliability,durability and working effectiveness.

Flexible equipment configuration, can be single unit independent production, can also cooperate with rough breaking equipment joint operation.

The vehicle chassis of medium crushing mobile crusher unit is higher, the body width is smaller than that of the operating semi-trailer, and the turning radius is small, which is convenient for driving in the rough and harsh road environment of the crushing field and more conducive to entering the construction area.

The configured impact crusher can not only crush certain first-line materials on site, but also directly produce finished sand and stone with ideal particle size. The working range is extended, but also reduce the transfer and transportation costs of materials. In addition, the medium crushing mobile crusher lengthening unit can also directly send the broken material to the transfer truck bucket, convenient and timely transportation.

The impact crushing principle of impact crusher produces better particle size of finished products, which can significantly improve the overall work efficiency of the mobile crushing station.

How mobile impact cruhser plant works? In the mining and quarry industry, mobile impact crusher plant is usually as secondary crushing machine to process rocks or ores from priamry jaw crusher plant. After impact crusher machine crushing, precisely shaped cubical end products is feed to vibrating screen to get different size material, 0-5mm, 5-10mm, 10-20mm, 20-40mm or some other required size. Vibrating screen is designed to be same level with impact crusher. The oversized material from first layer could be fed to impact crusher directly to crush again. Other required size is sent to stock ground by belt conveyor. Compared to stationary stone crusher plant, iIt has good mobility and can extend together with the raw materials site or construction site and has many types of combinations to satisfy the processing needs of different materials.

| Item | MJ-F1210 | MJ-F1214 | MJ-F1315 |

| Transportation Size(L*W*H)(mm) | 12000*2600*4200 | 13000*2600*4200 | 14000*2900*4500 |

| Max Size(L*W*H)(mm) | 14000*4000*6000 | 15300*4000*6500 | 16400*4300*6800 |

| Weight(t) | 39 | 44 | 52 |

| Configuration Of Tires | double axies | triaxial | triaxial |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 |

| Capacity(t/h) | 80-150 | 100-200 | 150-300 |

| Belt converyor under screen1 | B800*7m | B1000*8m | B1200*8m |

| Screen Model | 3YZS1848 | 3YZS1860 | 3YZS2160 |

Basalt

cobblestone

Dolomite

Marble

Limestone

Calcite

Potassium Feldspar

+86-13585707741*24-hourWhatsapp/Wechat